An Orillia company is hoping to produce and supply parts for masks and face shields during the COVID-19 pandemic.

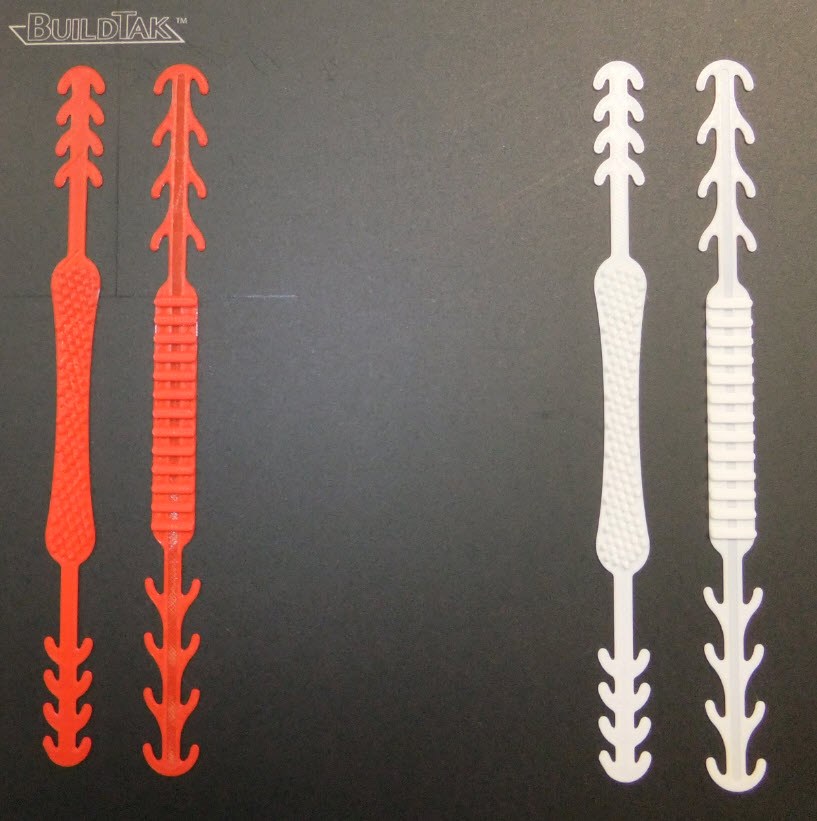

Kubota Materials Canada Corporation is putting its two 3D printers to use to create straps for face masks and, hopefully, adjusters for face shields, too.

The company has already made some of the straps and is awaiting more components before it can begin creating the face shield adjusters.

“We need a prototype to take to the hospitals to see if it meets their standards,” said Matthew Webb, Kubota’s senior manager of technology, noting he is waiting to hear back as to whether the products can be used.

Kubota is working with Georgian College, which has a laser cutter that can cut the clear plastic used for face shields. Kubota would produce the other plastic components of the shields.

Kubota purchased a 3D printer about a year-and-a-half ago and it recently acquired a second, larger one.

“3D printing is not the fastest thing,” Webb said, but he estimated Kubota could pump out components for about 10 face shields a day, and many more mask straps. “If we’re going to run these around the clock, we’re going to need to get some filament in.”

Like many companies, Kubota has had to reduce its staff during the pandemic, with many taking voluntary layoffs and others on leave.

“As far as the government is concerned, we are a part of the supply chain, so we are an essential service,” Webb said.

If the prototypes meet the standards of the health-care sector, Kubota is ready to step up, he added.

“We’re always trying to support our community,” he said, noting Kubota has donated to the Orillia Soldiers’ Memorial Hospital Foundation for the past decade. “We realize that the hospital is central to the well-being of the community. Everybody needs to come together and help out.”